Services

Start to finish

From concept to finished product, we guide our customers through the entire micro-transfer printing process.

We’re always available to answer questions or offer recommendations. Clients choose the level of support and services they need from us to support their projects.

1. Defining Requirements

Before we begin, NDA’s are signed to protect clients’ business intelligence and intellectual property.

At our first meeting, we provide an overview of the technology and answer questions about how it works. The next step is a discussion with the customer to understand their requirements:

- Review of the potential application

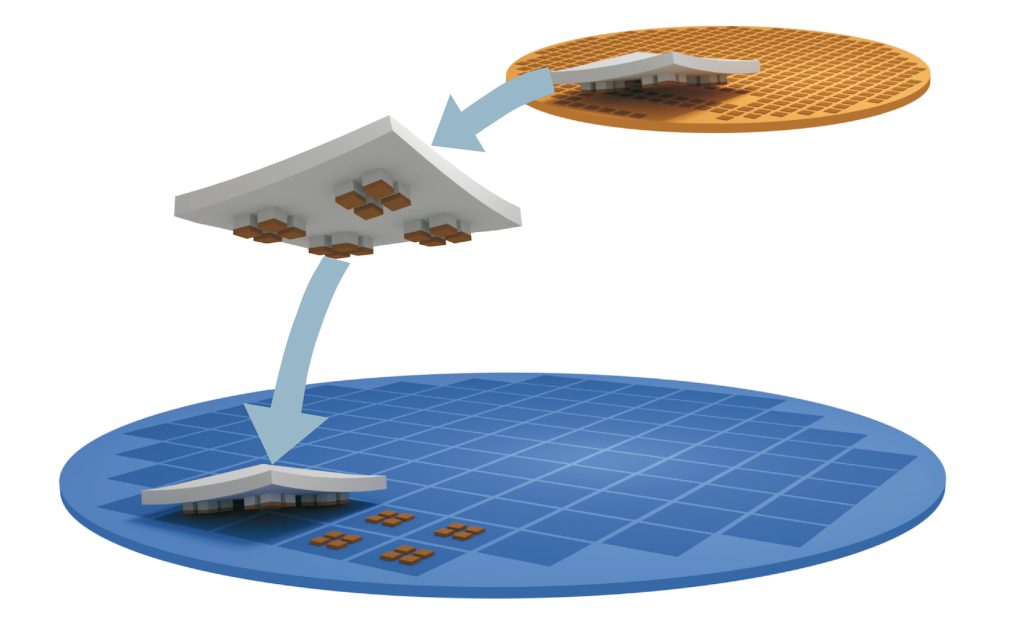

- Gain an understanding of components that need to be transferred (source) and where they need to be transferred (target)

- Review of a potential project/ SOW/budget

Once the scope of the project and budget are approved we move to the next phase, which begins with technology transfer.

Tyndall National Institute Clean Room

2. Design Support

The design phase is key to achieving the desired outcome. We work closely with clients to make sure their requirements are captured by the design documentation.

We approach design support in two ways:

- We provide guidance to the client’s team and they take the design process in-house or work with a vendor.

- We develop the design for the customer

The first step is guidance on creating transferable components. This includes spacing, alignment, and tether design information, the composition of the sacrificial and buffer layer, and target preparation. The customer either builds their own source device wafer or contracts with a vendor.

Design Management

- Design various levels to singulate the device with an etch and make it printable

- Purchase masks to support the requirements

- Pattern and etch to singulate and add tethers to allow the device to be undercut.

- Undercut the device to allow for micro-transfer printing

If the client is working with a vendor, they follow the same basic steps but do it at the vendor’s facility. If needed, we will consult on the design.

3. Prototypes

The prototype is the ultimate test of the design phase. Depending on the client’s needs, we provide the guidance and documentation to build a prototype using their own resources or we build the prototype for them.

The prototype process is as follows:

- The target is prepared with an adhesive as deemed by the surface roughness of the print site and application need.

- Print accuracy is measured.

- An oven cure post-print is done to cure the adhesive or promote the bond to the target wafer when no adhesive is used.

- A thin film interconnect process is completed to connect the device to the outside world or other components.

- The measurement and testing of the prototype are typically done at the client’s site. Changes and iterations can be made as needed.

4. Printing and Assembly

The production process is initiated when the prototype is finalized. The same steps are followed in preparing the final chip for printing. X-Celeprint has micro-transfer printing cleanroom labs at the Tyndall National Institute in Cork, Ireland, and in Research Triangle Park, NC.

Printed x-chips as small as 5 µm x 5µm, with x-chip to x-chip spacing of ~ 10 -20 µm and the thickness as thin as 1 µm. We can integrate multiple components on a single wafer, reducing the energy output for manufacturing with a high throughput rate.

There is more control over thermal conditions, which is significant for wearables and IoT devices. And there is increased energy efficiency, on trend with the industry’s interest in reducing its carbon footprint.

5. Licensing

A license is required to implement and practice MTP. Our clients can secure a license to practice MTP at any time during the process, although most wait until a prototype is developed and tested.

6. Tech Transfer to Commercialization

We have a large team of MTP experts and are ready to support you or a vendor under contract to scale up the technology to commercialization. We are also working with a number of potential vendors to supply print-ready components, and print-ready targets, as well as provide MTP printing services.

More information

X-Celeprint is an international leader in micro-transfer printing. Our headquarters are at the Tyndall National Institute in Cork, Ireland. We also have a Development Center in Research Triangle Park, NC. We serve customers in North America, Europe, and the Asia Pacific. We provide our clients with design support, prototyping, printing, licensing, and tech transfer for commercialization.